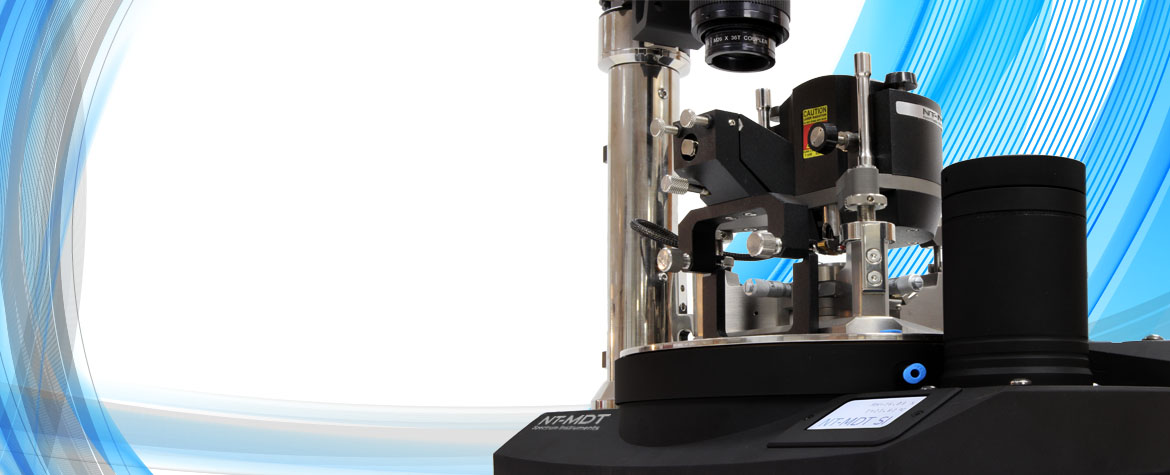

NTEGRA II

Legendary AFM with

advanced solutions

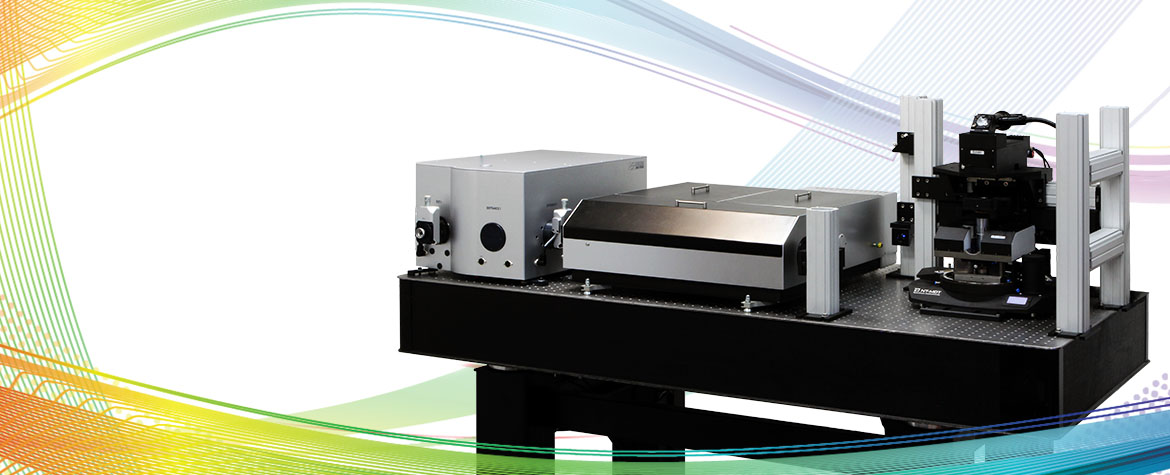

Wide range of tools

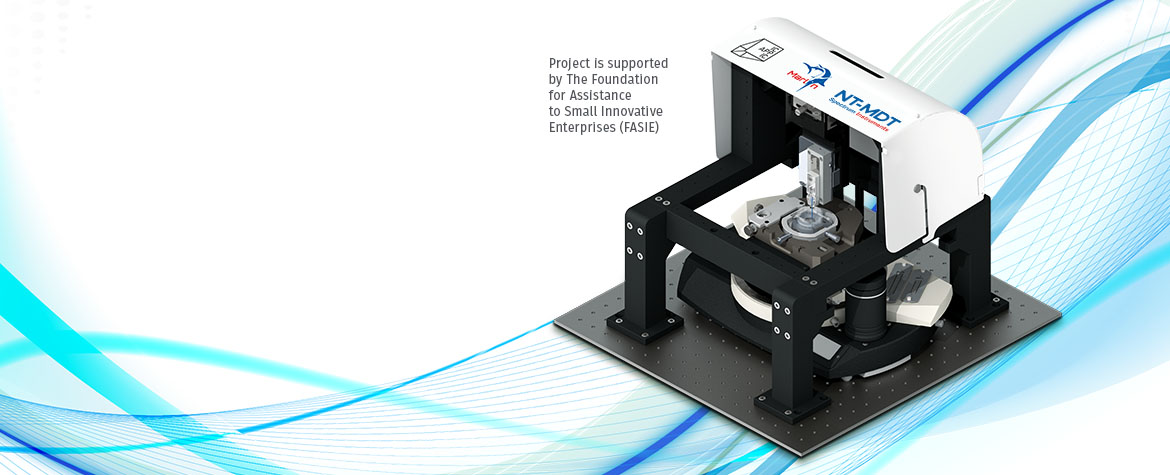

Multifunction HybriD Mode™ AFM

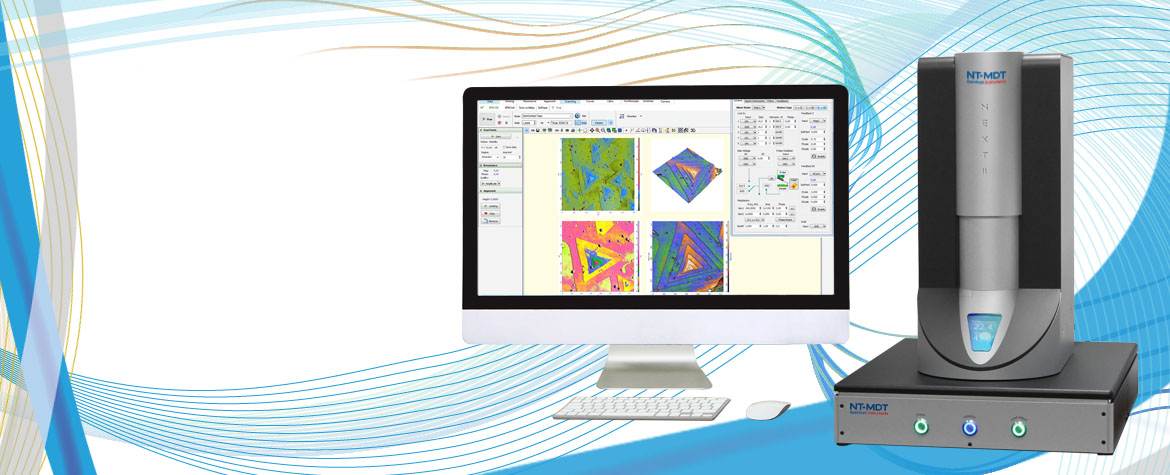

Intelligent software ScanT™

advanced solutions

Wide range of tools

Multifunction HybriD Mode™ AFM

Intelligent software ScanT™