W2C cantilevers crash test reveals unique stability

|

It’s well-known that results of Spreading resistance or LAO measurements depend strongly on a quality of tip-sample contact. In most cases its bad state is caused by a damage of tip’s end conductive layer due to its physical or electrical stress. In our opinion there are the two main schemes of possible cover’s crush:

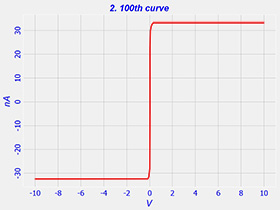

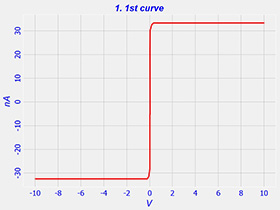

All the measurements were fulfilled by NT-MDT AFM’s Solver PRO and NTEGRA Prima. We took a piece of HOPG as a sample as it has got very high conductivity and allows to transfer very high current through a tip-sample contact area with our standard bias voltages. To examine tip’s apex resistivity to high voltage between a sample and a cantilever we carried out series of I(V) curves over the range -10V … +10V. Each curve took 4 seconds so that voltage changed slowly enough. On the images below you may see the first and the hundredth curves: |

|

|

|

|

As it looks from the images, there was no degradation detected after 100 I(V) curves in the same point. |

|

|

|

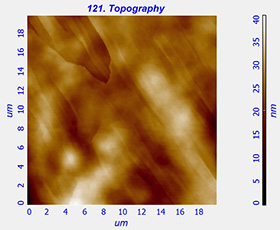

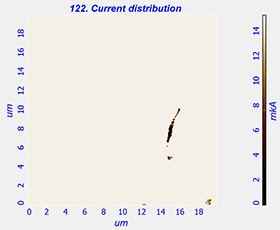

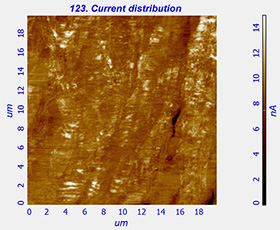

Current image of the same area during the next scan. It has got a similar non-conductive area as on the previous current scan but differs significantly from topography: |

|

|

|

Accounting on the results of our measurements, now we may approve that W2C conductive layer forms really strong conductive tip apex, which is wear-resistive and may even work for some time under extremely high voltage or current condition. We don’t recommend anybody to repeat these experiments continuously, stressing the probes. But after that result we may definitely say that W2C line of conductive cantilevers may provide stable and long work in standard measurements’ condition. |

|